What do consumers look for in a cooler?

The fisherman depending on a cooler to keep walleye fresh needs a very different product than the college kid looking at cold beer chests for a cookout. The casual cooler customer prioritizes price and size and cares less about performance and design. The high-end cooler buyer, on the other hand, considers the cooler to be an investment. For some, it can even be a critical one. Polystyrene and closed-cell polyethylene are not going to cut it, and the jump in price for a polyurethane cooler is worth it if it means avoiding spoiled food.

In this latter group, customers research and compare the durability and insulation of high-end coolers. They know what to look for, from the quality of the hinges to the locking straps to the thickness of the walls. These are the sort of details that separate the quality cooler from the rest.

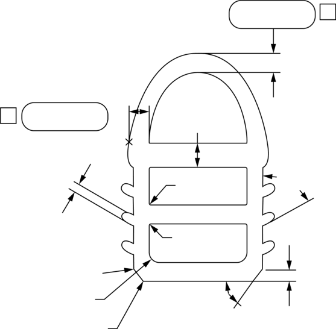

One crucial component of a quality cooler is the rubber lid seal. Without a seal, the interface between the lid and body of a cooler is between two rigid mating parts. A simple test on the effectiveness of such a joint would be to fill such a cooler with water, close the lid, tilt it on its side, and watch for leaks. Even if a such a cooler is watertight when new, eventually the lid will warp or expand and contract, and it will no longer make a tight seal. And if water can leak out, you can be sure that warm air can leak in.

A rubber seal is the ideal solution, because it compresses and recovers, ensuring a watertight seal over the long haul. The rubber seal must of course be food compatible, which is why you’re most likely to find them made from silicone or an FDA grade of thermoplastic rubber. PVC is sometimes used, but not recommended, because it can be too soft or too rigid at different temperature extremes and will become brittle over time as the plasticizer migrates out.

For our high-end cooler partners, the choice between silicone and thermoplastic rubber is an easy one. Both do the job equally well, but a silicone seal will cost 50-75% more than its thermoplastic rubber counterpart. Silicone rubber also tears much more easily than thermoplastic rubber, which presents a liability for adventuresome consumers.

If you are designing a well-insulated cooler, give us a call. We have lots of experience in the design and manufacturing of lid seals. We provide many of the top cooler manufacturers with their lid seals.